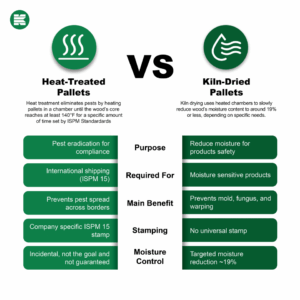

As a pallet user or buyer, you’ve likely encountered terms like “heat-treated pallets” (HT) and “kiln-dried pallets” (KD) when discussing your pallet needs. While both processes involve exposing wood to heat, they serve distinct purposes and are not interchangeable. Understanding the difference is crucial for making informed purchasing decisions that meet your specific operational and regulatory requirements.

Let’s break down the key distinctions

Heat-Treated (HT) Pallets: The Standard for International Shipping

What it is: Heat treatment is a process specifically designed to eliminate harmful pests that could be present in wood. Pallets are placed in a special chamber and heated until the core temperature of the wood or pallet reaches a minimum of 140 degrees Fahrenheit for at least 30 minutes. The total time it takes to actually heat-treat a stack or load of pallets varies from an hour to multiple hours. This total time depends on various factors including (but not limited to): weather conditions, indoor or outdoor placement of chamber, quality and age of chamber, and moisture content of the pallets.

Why it’s done: The primary and sole purpose of heat treatment is pest eradication. This process is mandated by the International Plant Protection Convention (IPPC) under the ISPM 15 (International Standards for Phytosanitary Measures No. 15) regulations. These regulations are in place to prevent the spread of invasive insects and diseases across international borders.

Key Characteristics and Benefits

- ISPM 15 Compliance: This is the most critical aspect. If you are shipping goods internationally, your wood packaging materials (including pallets) must be ISPM 15 compliant, which means they must be heat-treated and marked with the official “wheat stamp” or “bug stamp.”

- Pest-Free: Guarantees that your pallets are free from living insects and larvae, protecting global ecosystems.

- Does NOT Guarantee Moisture Content: While the heating process will remove some moisture, heat treatment is not designed to achieve a specific low moisture content. HT pallets can still have varying levels of moisture.

- Markings: HT pallets are easily identified by the ISPM 15 mark, which includes the IPPC logo, country code, producer code, and “HT” (for Heat Treatment).

When to Choose HT Pallets

- International shipments. This is non-negotiable for compliance in most situations.

- If your customer or industry specifically requires ISPM 15 compliance, even for domestic shipments (though less common).

Click Image to download our side-by-side HT vs KD Pallets chart

Kiln-Dried (KD) Pallets: Managing Moisture for Product Protection

What it is: Kiln drying is a controlled process that uses heated kilns to reduce the moisture content of wood to a specific, lower percentage. The wood is slowly and consistently dried, often to a target moisture content of around 19% or less, though this can vary based on specific needs.

Why it’s done: The primary purpose of kiln drying is moisture content reduction and stabilization. High moisture content in wood can lead to several problems.

Key Characteristics and Benefits

- Reduced Moisture Content: This is the defining characteristic. KD pallets have a significantly lower moisture content than green (undried) or even heat-treated only pallets.

- Reduced Risk of Mold and Fungus: Lower moisture content inhibits the growth of mold, mildew, and fungus, which can contaminate sensitive products or create an unappealing appearance.

- Greater Dimensional Stability: As wood dries, it shrinks. By drying the wood before pallet construction or use, KD pallets are less likely to warp, crack, or twist significantly after manufacturing, leading to more stable and consistent pallet dimensions.

- Lighter Weight: Less water content means lighter pallets, potentially reducing shipping costs.

- Improved Product Protection: Essential for products sensitive to moisture, such as paper products, food, pharmaceuticals, and electronics.

- No Specific Marking Requirement (for drying): There isn’t an equivalent “stamp” for kiln drying itself like there is for ISPM 15. Your supplier will provide documentation of moisture content.

When to Choose KD Pallets

- When shipping moisture-sensitive goods.

- If your storage environment is humid and you want to prevent mold growth on pallets.

- If you require consistent pallet weight for shipping calculations.

- To minimize the risk of pallet warping or dimensional changes.

Important Consideration for KD Pallets

It is important to note that while kiln-drying a pallet does reduce the pallet’s moisture content and reduce the risk of mold and fungus, it does not mean that moisture, mold, and fungus cannot be reintroduced to the pallet. It is important to always to abide by safe and sustainable pallet storage practices to prolong the life of your pallets and ensure the quality of your products.

Click here to read our tips and best practices for storing pallets.

Can a Pallet Be Both Heat-Treated (HT) and Kiln-Dried (KD)?

Yes, absolutely! In fact, it’s very common and often beneficial.

A pallet can first be kiln-dried to achieve a desired low moisture content (e.g., 19%) and then, if required for international shipping, be heat-treated to meet ISPM 15 pest eradication standards. In this scenario, the pallet would carry the ISPM 15 stamp, and your supplier would provide documentation regarding the kiln-dried moisture content.

The Takeaway for Smart Pallet Purchasing

- International Shipping? You will need HT pallets.

- Shipping Moisture-Sensitive Goods? You should consider the added protection of KD pallets.

- Concerned about Mold or Pallet Stability? KD is your answer.

- Both? Absolutely! If you ship sensitive products internationally, a pallet that is both KD and HT provides the best of both worlds: pest-free and moisture-controlled.