Our Green Scorecard

Our vision is a world where supply chains produce zero wood waste and have a positive impact on our climate and ecosystems.

This was our impact last year.

What will yours be?

recycled pallets purchased or sold is equivalent to:

-

Trees Saved

-

Tons of Landfill Diversions

-

Metric Tons of CO2 Avoided

-

Passenger Vehicles Worth of Emissions

Building a more sustainable world, one pallet at a time

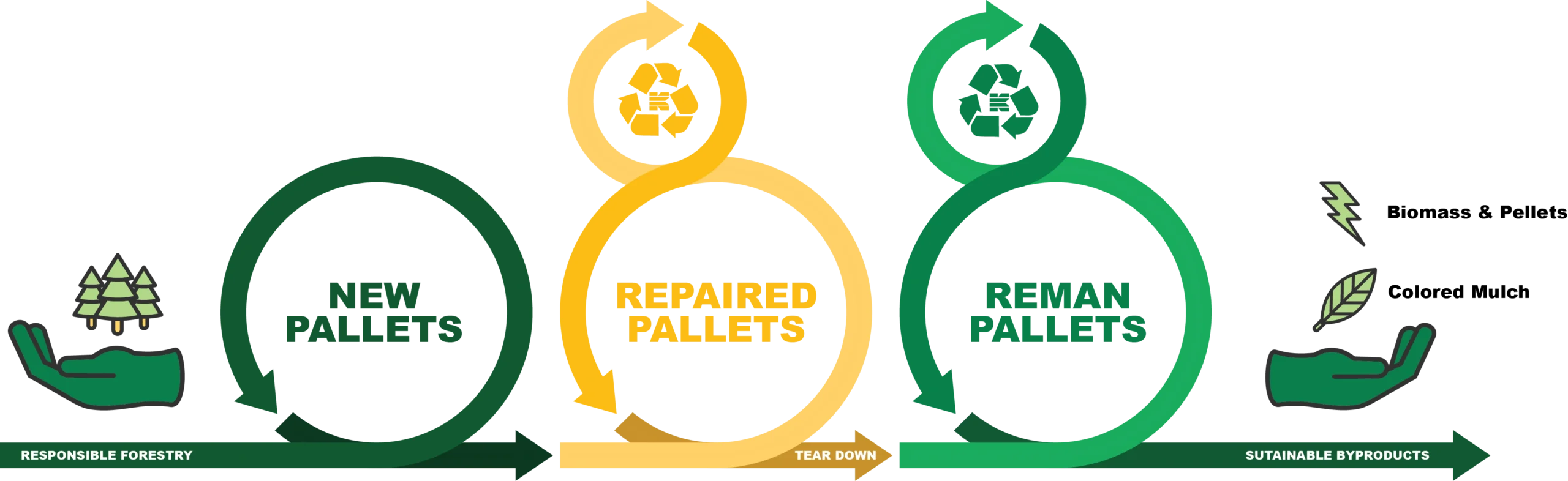

To achieve our sustainability vision, Kamps has made significant investments at all stages of our “Sustainable Pallet Life-Cycle” to ensure we have the most comprehensive supply chain coverage for our customers and vendors.