As a national pallet company, Kamps understands that a pallet is far more than just a wooden platform. It’s a critical component of the supply chain, designed to withstand diverse conditions and protect valuable goods. A key factor in a wooden pallet’s performance, longevity, and even its cost, lies in the type of lumber it’s made from. This isn’t a one-size-fits-all scenario; the choice between hardwood and softwood, and even specific species within those categories, is a strategic decision influenced by the pallet’s intended application and, perhaps surprisingly, the regional location of our facilities and our customers.

Why Wood Species Matters

The characteristics of different tree species directly translate to the properties of a pallet:

Strength and Durability

Hardwoods, typically denser due to their slower growth, offer superior strength and resistance to wear and tear. This makes them ideal for heavy-duty applications, repeated use, and situations where pallets will endure rough handling. Softwoods, while generally lighter and easier to work with, still provide significant strength.

Weight

Softwood pallets are typically lighter than their hardwood counterparts of similar dimensions. This can lead to cost savings in transportation, especially for air freight or when weight limits are a concern. Lighter pallets also ease manual handling for workers.

Cost and Availability

The abundance and growth rate of a tree species directly impact its cost. Fast-growing softwoods are often more readily available and thus more economical. Hardwoods, with their slower growth, can be more expensive.

Moisture Content and Treatment

Softwoods are often kiln-dried to reduce moisture content, enhancing their stability and resistance to mold. Both hardwoods and softwoods can be heat-treated (HT) to meet ISPM 15 international regulations for pest prevention in global shipments.

Sustainability

Responsible forestry practices are crucial for both hardwoods and softwoods. The faster growth cycle of softwoods can make them a rapidly renewable resource, while the longer lifespan of durable hardwood pallets can reduce the overall demand for new timber over time.

The Impact of Regional Location

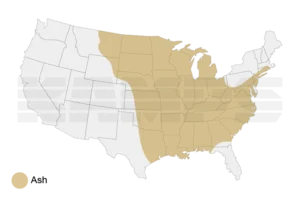

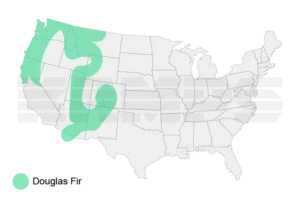

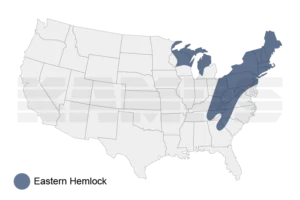

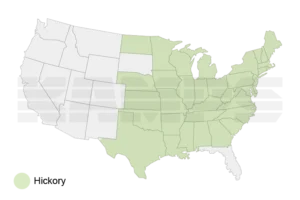

The United States is rich in diverse forest ecosystems, and this geographical distribution of tree species directly influences the types of wood used in pallet manufacturing across different regions. Pallet manufacturers often source lumber from locally grown forests to minimize transportation costs, lower environmental impact, and ensure a consistent supply.

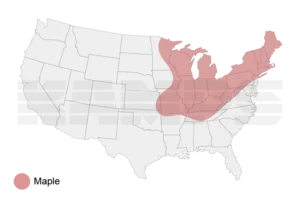

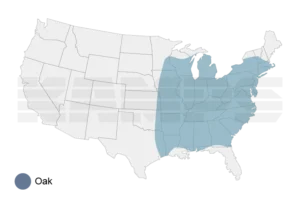

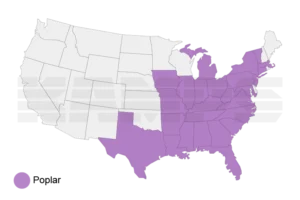

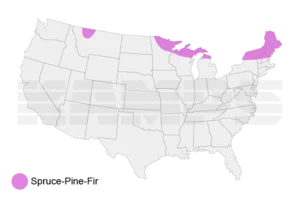

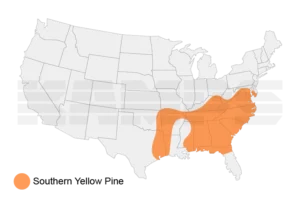

United States Native Tree Species Map

Use the gallery below to see where each tree species grows in the United States. Click on each map to enlarge.

Sources: https://www.fs.usda.gov/foresthealth/technology/pdfs/fieldguide.pdf, https://www.finewoodworking.com/2024/08/19/hard-maple-vs-soft-maple, https://www.gettingmoreontheground.com/2019/07/21/ash-trees-a-celebration-and-a-lament/, https://www.foragingtexas.com/2008/09/hickory.html, https://www.fs.usda.gov/database/feis/plants/tree/lirtul/all.html, https://www.woodsmith.com/article/choosing-pine-pine-grades/, https://www.nps.gov/brca/learn/nature/douglasfir.htm, https://www.fs.usda.gov/database/feis/plants/tree/picgla/all.html, https://en.wikipedia.org/wiki/Tsuga_canadensis

Northeast

This region is characterized by vast deciduous forests, making hardwoods like oak, maple, birch, and ash readily available. Pallets from the Northeast often leverage the strength and durability these species offer for heavy-duty applications.

Southeast

The Southeast is abundant in pine forests, particularly Southern Yellow Pine. This softwood, despite its classification, is known for its considerable strength and stiffness, making it a popular choice for cost-effective and durable pallets.

Midwest

The Midwest presents a mix of both hardwoods (birch, maple, poplar) and softwoods (hemlock, pine) in its northern parts. This allows for flexibility in pallet construction, balancing strength and cost-efficiency based on specific needs.

West Coast

The vast coniferous forests of the West Coast primarily offer softwoods like spruce, pine, and fir (often referred to as SPF). These lighter, more affordable softwoods are favored for pallets where cost and shipping weight are key considerations.

Summary

By understanding the unique properties of each tree species and their geographical distribution, Kamps can make informed decisions that optimize pallet performance, cost-effectiveness, and sustainability for our diverse customer base across the nation.