What are heat-treated pallets?

Heat-treated pallets, sometimes referred to as HT pallets, are wooden pallets that have been heated in a chamber to a core temperature of at least 140 degrees Fahrenheit. The wooden pallets must be kept at this temperature for at least 30 minutes. Heat-treated pallets are primarily used to export products outside of the United States. However, there are a few other benefits that we will also explore later in the article.

Why do pallets need to be heat-treated?

Wood pallets are made from organic material – trees. Trees do not grow in sterile surroundings. The ground they are rooted in, the air they are surrounded by, and the water they absorb are full of nourishing materials but also home to many pests. These pests, whether mature or in larval stage, are easily transported from one area of the world to another in the wood they inhabit. Transporting these pests to a part of a world they are not native to can cause many problems to the importing country’s ecosystems and natural habitat.

Because of this, governments, environmentalists, and pallet makers have developed various methods to eliminate pests during the pallet production stage. The two most popular treatments are methyl bromide fumigation and heat-treatment. Methyl bromide is a chemical fumigation process that effectively kills pests but has been largely phased out due to its harmful environmental effects and health risks. In contrast, heat-treatment (HT) involves heating the wood to a specific temperature to eliminate pests, a more eco-friendly approach.

Click here to learn more about the negative effects of Methyl Bromide from the EPA.

It is widely agreed upon in the wooden pallet and packaging industry that heat-treatment is the more acceptable process as it does not utilize any chemicals – thus making it safer for the environment, employees handling the product, and end consumers.

Exporting With Heat-Treated Pallets

Heat-treated pallets are required for all wood packaging material used in international shipments. Heat-treating is one of the necessary steps for ensuring the safety of the product being shipped as well as the environment of the product’s destination.

What is the process for heat-treating pallets?

Heat-treatment for pallets is a phytosanitary process developed by the International Plant Protection Convention (IPPC) that aims to secure “coordinated, effective, action to prevent and to control the introduction and spread of pests of plants and plant products”.

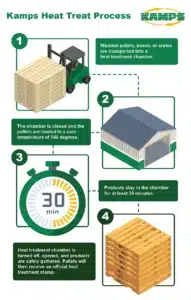

The steps of a heat-treatment process

- Wooden pallets, boxes, or crates are transported into a heat-treatment chamber

- A hole is drilled into the wooden product and a temperature gauge or rod is placed in the product. This gauge or rod will confirm the internal temperature of the product.

- The chamber is closed and the pallets are heated to a core temperature of 140 degrees Fahrenheit, ensuring all insects and larvae are killed.

- Products stay in the chamber for at least 30 minutes.

- Heat-treatment chamber is turned off, opened, and products are safely retrieved.

Click on photo below to expand and download as a takeaway visual

What are the benefits of the process?

The main benefit of heat-treating a pallet is pest elimination and successful export capabilities. However, there are several potential add-on bonuses that do exist.

One of those benefits is potentially extending the life of your pallet. When you rid a pallet of pests, you are increasing the amount of times that you can continue using it, before it starts to break down due to pest issues. It is important to note that other environmental and outside factors can still impact the life of your pallet.

Heat-treating pallets can have also help lower the moisture content of a pallet. While the process does not impact the moisture content of a pallet as much as kiln-drying would, it still stands as a potential add-on bonus due to the natural occurrence of moisture leaving the pallet in the warm chamber.

Picture of a standard Heat-Treatment Chamber (Photo taken from Kamps San Antonio, TX facility)

What is ISPM-15?

ISPM-15, or International Standards for Phytosanitary Measures No. 15, is a set of regulations created by the International Plant Protection Convention (IPPC). These standards define the required treatments and procedures for wood packaging materials (WPM) used in international shipping to prevent the spread of invasive pests. ISPM-15 requires heat treatment or fumigation to ensure compliance and minimize the risk of pest infestations across the world.

Click here to download the full ISPM-15 regulations (PDF).

Adhering to ISPM-15 standards and rules is important because non-compliance can lead to costly supply chain disruptions and/or legal penalties. It is a standard practice for importing countries to hold products at customs if heat treatment certifications and stamps are not up to date and verifiable. This is why it is important to work with a trusted and audited heat-treated pallet provider.

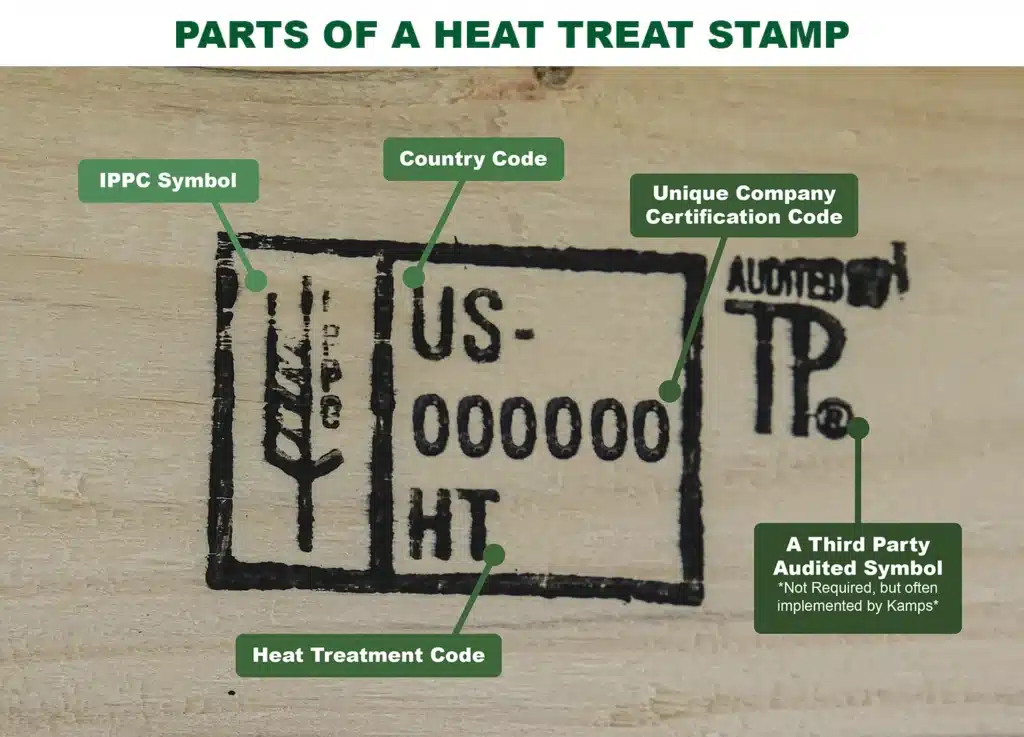

Image below of all the important parts of a heat-treat stamp on a pallet

Leading the way in heat-treatment

Kamps Pallets is a pallet company certified to perform the heat-treatment process necessary to comply with ISPM-15 standards. We have experience adhering to ISPM-15 standards since they were implemented in 1993. We have certified and annually audited plants nationwide, and can produce large numbers of heat-treated pallets for our clients throughout the U.S.

If your company needs heat-treated pallets, please contact us to discuss how we can meet your need together

This article was originally published on 6/30/2015 and updated to include more recent and expanded information on 3/10/2025.